-

-

{{item.name}}

{{classTitle_1}}-

{{item.name}}

{{classTitle_2}}-

{{item.name}}

{{classTitle_3}}{{classInfo.name}} -

-

{{'Company Profile' | capitalizeWords}}

{{'Company Profile' | capitalizeWords}}

-

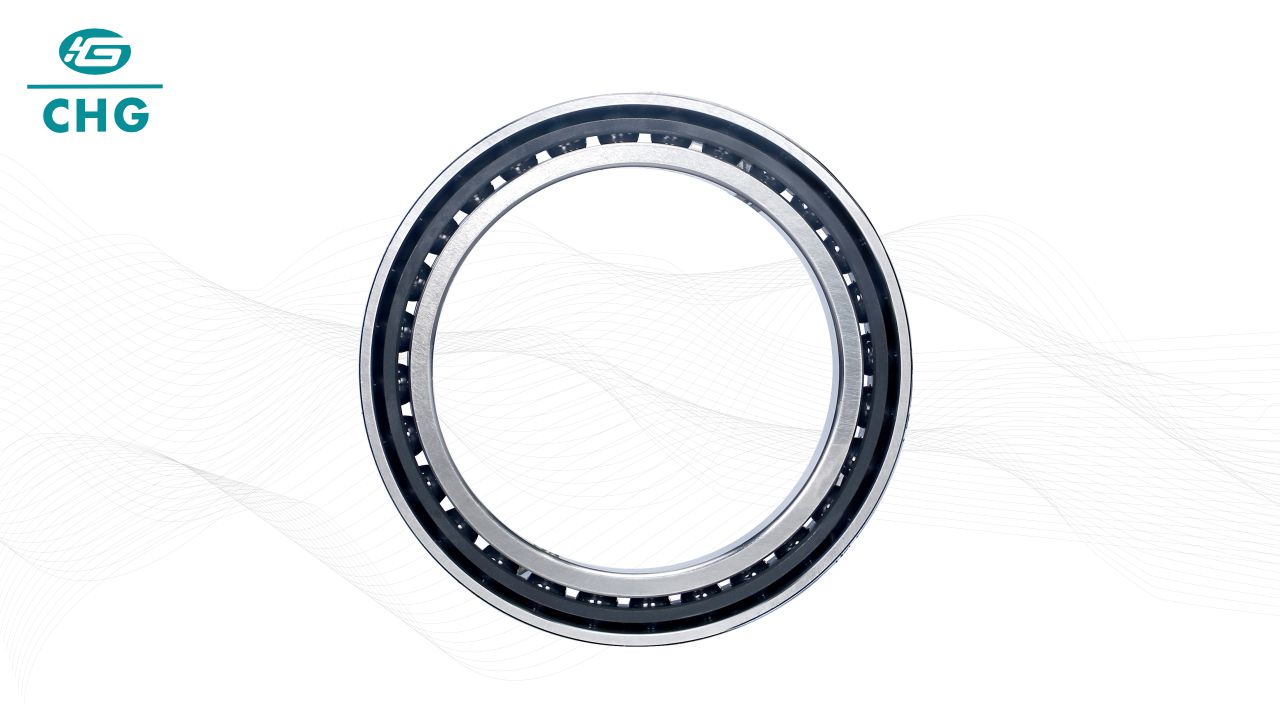

Thin Section Bearings

Thin Section Bearings -

heavy-duty bearings

heavy-duty bearings -

Slewing Bearing

Slewing Bearing -

Rolling Element

Rolling Element

Company Profile-

{{item.name}}

{{classTitle_1}}-

{{item.name}}

{{classTitle_2}}-

{{item.name}}

{{classTitle_3}}{{classInfo.name}} -

-

{{'Bearing products' | capitalizeWords}}

{{'Bearing products' | capitalizeWords}}

-

Thin Section Bearings

Thin Section Bearings -

heavy-duty bearings

heavy-duty bearings -

Slewing Bearing

Slewing Bearing -

Rolling Element

Rolling Element

Bearing products-

{{item.name}}

{{classTitle_1}}-

{{item.name}}

{{classTitle_2}}-

{{item.name}}

{{classTitle_3}}{{classInfo.name}} -

-

{{'Technical Support' | capitalizeWords}}

{{'Technical Support' | capitalizeWords}}

-

Thin Section Bearings

Thin Section Bearings -

heavy-duty bearings

heavy-duty bearings -

Slewing Bearing

Slewing Bearing -

Rolling Element

Rolling Element

Technical Support-

{{item.name}}

{{classTitle_1}}-

{{item.name}}

{{classTitle_2}}-

{{item.name}}

{{classTitle_3}}{{classInfo.name}} -

-

{{'Company News' | capitalizeWords}}

{{'Company News' | capitalizeWords}}

-

{{item.name}}

{{classTitle_1}}-

{{item.name}}

{{classTitle_2}}-

{{item.name}}

{{classTitle_3}}{{classInfo.name}} -

-

{{'Contact us' | capitalizeWords}}

{{'Contact us' | capitalizeWords}}

-

{{item.name}}

{{classTitle_1}}-

{{item.name}}

{{classTitle_2}}-

{{item.name}}

{{classTitle_3}}{{classInfo.name}} -